Technology Description

Soil Vapor Extraction (SVE) is an in-situ remediation technology used to remediate soils affected with volatile organic compounds (VOCs) including gasoline and chlorinated hydrocarbons. This technology works by installing wells and using blowers to induce a vacuum and extract vapors from the subsurface. The vadose zone is remediated through the following mechanisms: (1) capture of soil gas in the vadose zone; (2) pneumatic control of soil gas and VOCs in the area around the wells; (3) volatilization of free product, and; (4) desorption of VOCs in soil. The soil vapor extracted from the subsurface is conveyed to an air emissions control system to remove the toxic compounds prior to atmospheric discharge. The design, construction, and operation of SVE systems require permitting and operation in compliance with air emissions regulations.

SVE System Design

We implement proven designs into our SVE systems for ongoing process optimization and to shorten the site remediation timeframe. These proven designs allow us to obtain regulatory closure of sites with chemically affected soil.

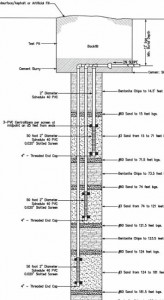

SVE System Installation

Whenever possible, the SVE well locations are selected to create a capture zone that extends beyond the VOC plume boundaries. To optimize the well configuration, numerical airflow models can be used to simulate subsurface airflow conditions. The final SVE system design generally includes multi-depth extraction well networks. SVE air emission control systems are selected based on the toxic compounds and their concentrations. We use thermal oxidation (ThermOx) systems, catalytic oxidation (CatOx) systems, vapor phase granular activated carbon (VPGAC), and rotary thermal oxidizers (RTOs).

SVE System Operation and Maintenance

Operation activities include the following: (1) monitoring system pressures, air flows, and temperature; (2) estimating VOC mass removal rates; (3) monitoring of concentrations and sampling of influent and effluents to record compliance with air emissions permits; and (4) monitoring and maintenance of process equipment, including mechanical and electrical equipment. Periodic progress reports are prepared to document the remediation progress, update regulatory agencies, and compile data to support eventual site-closure requests.

Process Optimization

SVE wells and systems are designed to continuously optimize extraction. The SVE system configuration and piping at the manifolds are designed to operate those SVE wells with high VOC mass removal rates, and close SVE wells with low VOC mass removal. The optimization process in combination with the soil vapor data are used to induce different subsurface air flow dynamics and target remediation of recalcitrant areas.

Regulatory Support

Regulatory support is provided throughout the implementation of the project with the lead regulator by: preparing plans, preparing remedial action plans (corrective action), sampling plans, and operations and maintenance reports.

SVE Remediation Services

- Feasibility Studies

- Remedial Action Plans

- Pilot Testing

- Permitting

- Remediation System Design

- Construction

- Operation and Maintenance Manuals

- Training

- Operation and Maintenance

- Remediation System Optimization

- Estimation of Mass Removal Rates

- Reporting to Clients and Regulatory Agencies

- Annual Performance Assessment Reports

- Closure Assessment Reports

- Closure Requests