Process Description

The advanced oxidation with ozone and peroxide is a proven technology for the oxidation of a wide range of compounds in water. The units are highly automated and can be easily installed to treat water and remediate groundwater impacted with BTEX, MtBE, TPH-g, total petroleum hydrocarbons as diesel (TPH-d), tert-butyl formate (TBF), tert-butyl alcohol (TBA), tert-amyl methyl ether (TAME), diisopropyl ether (DIPE), polyaromatic hydrocarbons (PAHs), trimethylbenzene, 1,4-dioxane, trichloroethylene (TCE), perchloroethylene (PCE), 1,2-dichloroethene (1,2-DCE), 1,1-dichloroethene (1,1-DCE), vinyl chloride, and tetrahydrofuran.

Advanced Oxidation Description

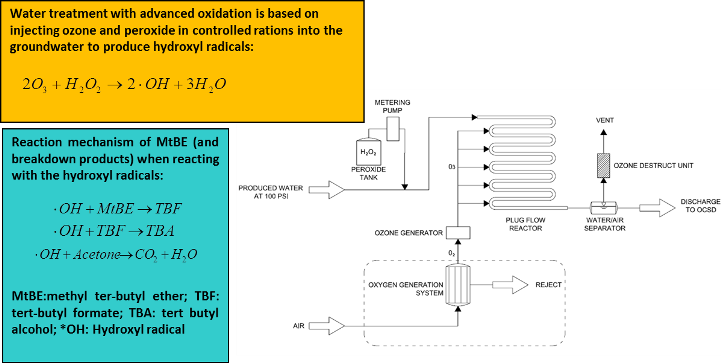

Advanced oxidation systems for water treatment are designed to inject ozone and peroxide in controlled ratios into the water, and then mix the oxidizing agents to form hydroxyl radicals (·OH). Ozone (O3), peroxide (H2O2), and hydroxyl radicals are strong oxidizing agents capable of oxidizing benzene, toluene, ethylbenzene, and xylenes (BTEX), gasoline range organics, and oxygenates. The final products resulting from the complete oxidation of organics and oxygenates are carbon dioxide and water.

Plug Flow Reactor System Configurations

In water and wastewater treatment applications, the oxidation reaction occurs in a plug-flow reactor, and the reactor is fully automated and PLC controlled. These reactors are provided by reputable vendors with a track record in supplying systems that are highly automated, and reliable. We assist our clients in implementing these systems by designing, constructing treatment systems, and implementing advanced oxidation systems at the center of these processes.

Engineering Services

Engineering services include the following: Bench scale and pilot testing, cost estimating, regulatory support, permitting, design, installation, operation, process monitoring, data analysis and reporting and demobilization.

In general, the advanced oxidation process is reliable due to a high degree of automation, instrumentation and control, and offers functional advantages over other technologies including activated carbon. In some cases, advanced oxidation may be as cost effective as activated carbon. In specific cases, advanced oxidation was estimated to have higher capital costs but similar mid to long term costs compared to inflation when accounting for operations costs, and net present value.