Process Description

The in-situ remediation of groundwater with ozone and hydrogen peroxide is a technology for the oxidation of petroleum and chlorinated hydrocarbons. The units are highly automated and can be easily installed to treat groundwater impacted with benzene-toluene-ethylbenzene-xylene (BTEX), methyl tert-butyl ether (MtBE), total petroleum hydrocarbons as gasoline (TPH-g), total petroleum hydrocarbons as diesel (TPH-d), tert-butyl formate (TBF), tert-butyl alcohol (TBA), tert-amyl methyl ether (TAME), diisopropyl ether (DIPE), polyaromatic hydrocarbons (PAHs), trimethylbenzene, 1,4-dioxane, trichloroethylene (TCE), perchloroethylene (PCE), 1,2-dichloroethene (1,2-DCE), 1,1-dichloroethene (1,1-DCE), vinyl chloride, and tetrahydrofuran.

Advanced Oxidation Description

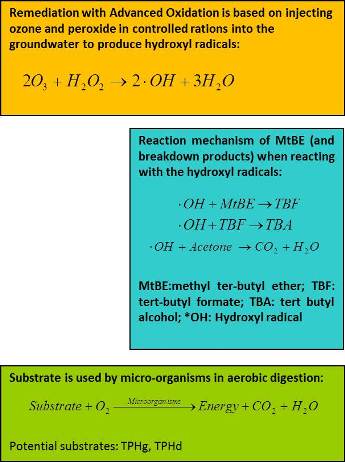

Advanced oxidation remediation systems are designed to inject ozone and peroxide in controlled ratios into the groundwater, and then mixing the oxidizing agents to form hydroxyl radicals (·OH). Ozone (O3), peroxide (H2O2), and hydroxyl radicals are strong oxidizing agents capable of oxidizing benzene, toluene, ethylbenzene, and xylenes (BTEX), gasoline range organics, and oxygenates. The final products resulting from the complete oxidation of organics and oxygenates are carbon dioxide and water.

Groundwater Remediation with Advanced Oxidation

Hydroxyl radicals are very reactive and have a high electrochemical oxidation potential (EOP) compared to other available oxidizing agents. Hydroxyl radicals have an EOP of 2.8 Volts (V), and ozone has an EOP of 2.08 V. As a reference, the EOP of chlorine, which is an effective oxidizing agent widely used for disinfection of water is 1.36 V, and lower than the EOPs of both ozone and hydroxyl radicals.

The process releases unused oxygen as a byproduct, which may be used by microorganisms (when established) to oxidize the available substrate in soil and groundwater through aerobic biodegradation. A substrate may include any source of carbon (i.e., MtBE, BTEX, and TPH-g).

The advanced oxidation system can oxidize petroleum compounds including BTEX, MtBE, TPH-g, total petroleum hydrocarbons as diesel (TPH-d), tert-butyl formate (TBF), tert-butyl alcohol (TBA), tert-amyl methyl ether (TAME), diisopropyl ether (DIPE), polyaromatic hydrocarbons (PAHs), and trimethylbenzene.

Other compounds targeted directly or indirectly by the advanced oxidation include 1,4-dioxane, trichloroethylene (TCE), perchloroethylene (PCE), 1,2-dichloroethene (1,2-DCE), 1,1-dichloroethene (1,1-DCE), vinyl chloride, and tetrahydrofuran.

Project Implementation for Groundwater Treatment

Project implementation services include bench scale and pilot testing, cost estimating, regulatory support, permitting, design, installation, operation, groundwater monitoring, data analysis, reporting, and demobilization.

The design of chemical injection wells including well depth, materials, screened intervals, distribution and estimated radius of influence is prepared based on site-specific characteristics such as plume size, soil conditions, and targeted levels of compliance.

In general, the advanced oxidation process is reliable due to the high degree of automation and offers functional advantages over other technologies. The technology can reduce the remediation time by years when compared to pump and treat technologies. Our experience with advanced oxidation includes sites with impacted groundwater by leaking UST tanks, produced water from oil and gas extraction and lake water treatment systems.

Oxidation Barriers

For properties where MTBE is mobile and migrating offsite, the wells can be arranged to form an oxidation barrier and stop MTBE mass from moving offsite. Offsite migration of MTBE can lead to action on behalf of regulators or can complicate the legal issues associated with plume commingling.

The oxidation barriers can be installed to oxidize the chemical compounds in water flowing across the barrier and chemicals moving through the barrier through diffusion.