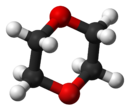

The development plan for a former manufacturing site located in Westlake Village included the construction of a luxury hotel. Seventeen underground storage tanks, four clarifiers, and two sumps associated with the former media manufacturing operations had impacted the groundwater with several chemicals of concern including 1,1,1-TCA, 1,1-DCE, PCE, TCE, cis-1,2-DCE, 1,1-DCE, 1,1-DCA, 1,2-DCA, vinyl chloride, chloroform, Freon-113, and 1,4-dioxane. The building’s basement was expected to produce 20 gallons per minute of underflow that required treatment prior to discharge into the storm drain. The work included performing a feasibility study to identify the most cost-effective method to dispose of groundwater. The feasibility study identified advanced oxidation as the only technically feasible reduction technology for 1,4-Dioxane. The advanced oxidation process was followed by liquid phase activated carbon (LPGAC) treatment system to remove residual ozone and some VOCs which are not removed by the advanced oxidation process. The follow-up work included preparing a detailed design, preparing NPDES permits for storm water discharge, process flow diagrams, layout diagrams, and process and instrumentation diagrams.

Categories

Search

Other Categories